Grasping the Embroidery Digitizing Refine: Your Ultimate Overview

Embroidery digitizing is a meticulous craft that calls for precision and expertise to convert complex layouts right into electronic formats for machine needlework. As craftsmens embark on this journey to grasp the needlework digitizing process, a detailed understanding of the fundamentals establishes the structure for excellence.

Recognizing Needlework Digitizing Fundamentals

Needlework digitizing essentials develop the foundation upon which intricate styles are translated into machine-readable formats for exact sewing. This preliminary action in the needlework digitizing process is critical for guaranteeing that the final stitched product is a devoted representation of the initial design. Understanding embroidery digitizing fundamentals entails grasping vital principles such as stitch types, sew direction, thickness, padding, and draw compensation.

Stitch kinds play a vital role in figuring out the visual and textural outcome of the embroidered layout. By selecting the suitable stitch kind, whether it be satin, fill, or running stitch, digitizers can achieve the preferred result and boost the overall top quality of the needlework. In addition, sew instructions influences the flow and dimension of the style, while thickness establishes the spacing and insurance coverage of the stitches.

Moreover, rug stitching supplies stability to the layout by safeguarding the textile and protecting against distortion during the needlework process. Pull payment is an additional vital consideration to neutralize the natural tendency of textile to contract when sewn. Mastering these needlework digitizing basics is essential for producing professional-quality embroidered items.

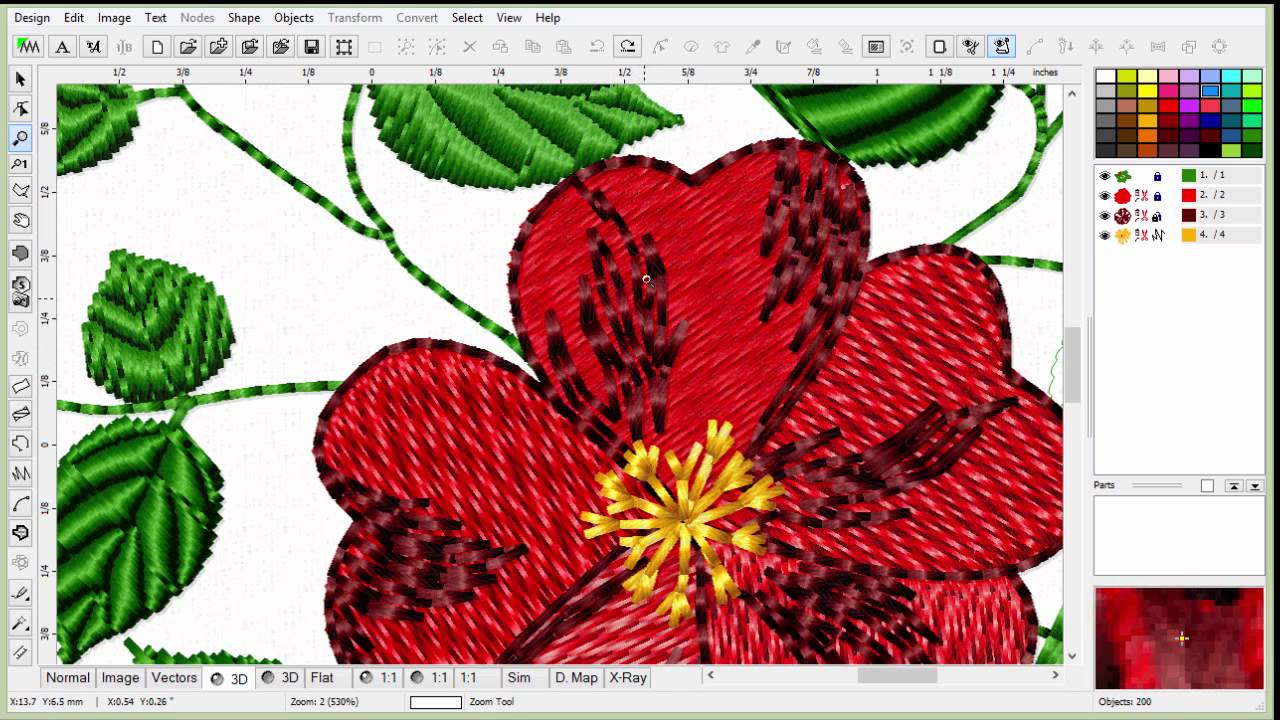

Selecting the Right Digitizing Software

Picking the suitable digitizing software is an essential decision that substantially impacts the effectiveness and top quality of the embroidery digitizing process. Digitizing for Embroidery. When picking the right digitizing software application, it is important to consider elements such as the intricacy of styles you plan to create, the user-friendliness of the software, the level of customer assistance used, and the compatibility with your embroidery equipment

There are different digitizing software program options available out there, ranging from standard programs for beginners to advanced software program for expert digitizers. Some popular options include Wilcom EmbroideryStudio, Hatch Needlework Software Application, and PulseID. These software supply a large range of devices and functions to assist you develop elaborate designs with convenience.

Before making a choice, it is a good idea to check out the different software program options via totally free trials or demos to identify which one best suits your demands. Additionally, checking out testimonials and seeking recommendations from experienced digitizers can offer useful understandings right into the staminas and weak points of each software application bundle (Digitizing for Embroidery). By carefully examining your needs and comparing the functions of different digitizing software, you can make an enlightened choice that enhances your embroidery digitizing process

Digitizing Tools and Techniques

Optimizing Design Settings for Needlework

Grasping the ins and outs of layout setups is basic in attaining optimum cause the embroidery digitizing process, building upon the structure laid by comprehending digitizing tools and methods. When optimizing design setups for needlework, it is necessary to consider elements such as stitch kind, density, padding, pull compensation, and enrollment. Stitch kind choice influences the general look of the design, with options like satin, fill, and running stitches supplying different textures and effects. Thickness refers to the spacing and thickness of stitches, affecting the layout's coverage and toughness. Correct underlay sewing offers security and protects against material distortion, especially for complex designs or on elastic materials. Draw payment adjusts for fabric stretch throughout sewing, making certain accurate style replication. Enrollment setups straighten various elements of the design precisely, preserving overall style honesty. By fine-tuning these layout settings, embroiderers can enhance the high quality and precision of their embroidered productions.

Troubleshooting Common Digitizing Issues

When experiencing typical digitizing problems during the embroidery process, it is necessary to comprehend the source and implement efficient solutions promptly. One typical problem is stitch density issues, where stitches may be too thick, triggering the fabric to tighten, or also sporadic, resulting in spaces in the style. Changing the stitch density setups in the digitizing software application can help fix this issue.

An additional frequent challenge is string breaks during the embroidery procedure. This can occur as a result of numerous factors such as wrong stress settings, boring needles, or using low-grade string. Guaranteeing proper upkeep of the embroidery maker, consisting of routine needle changes and tension changes, can minimize the incident of string breaks.

Moreover, style registration like this mistakes can result in misaligned components within the embroidery style. Checking the layout alignment in the digitizing software application and making essential modifications prior to stitching can assist in preventing this concern. By addressing these usual digitizing issues quickly and efficiently, you can guarantee a smoother embroidery procedure and high-grade ended up items.

Verdict

Finally, understanding the embroidery digitizing procedure calls for a solid understanding of the essentials, the appropriate YOURURL.com selection of software application, and understanding of tools and methods. Optimizing layout setups and troubleshooting common digitizing issues are crucial action in making sure top notch embroidery results. By following these actions vigilantly, one can achieve accuracy and efficiency in the digitizing procedure.